From meticulous selection of materials to flawless finishes, everything our artisans do attests to exceptional skill and craft. Discover the fascinating journey of a Maison Boinet belt, from design to production.

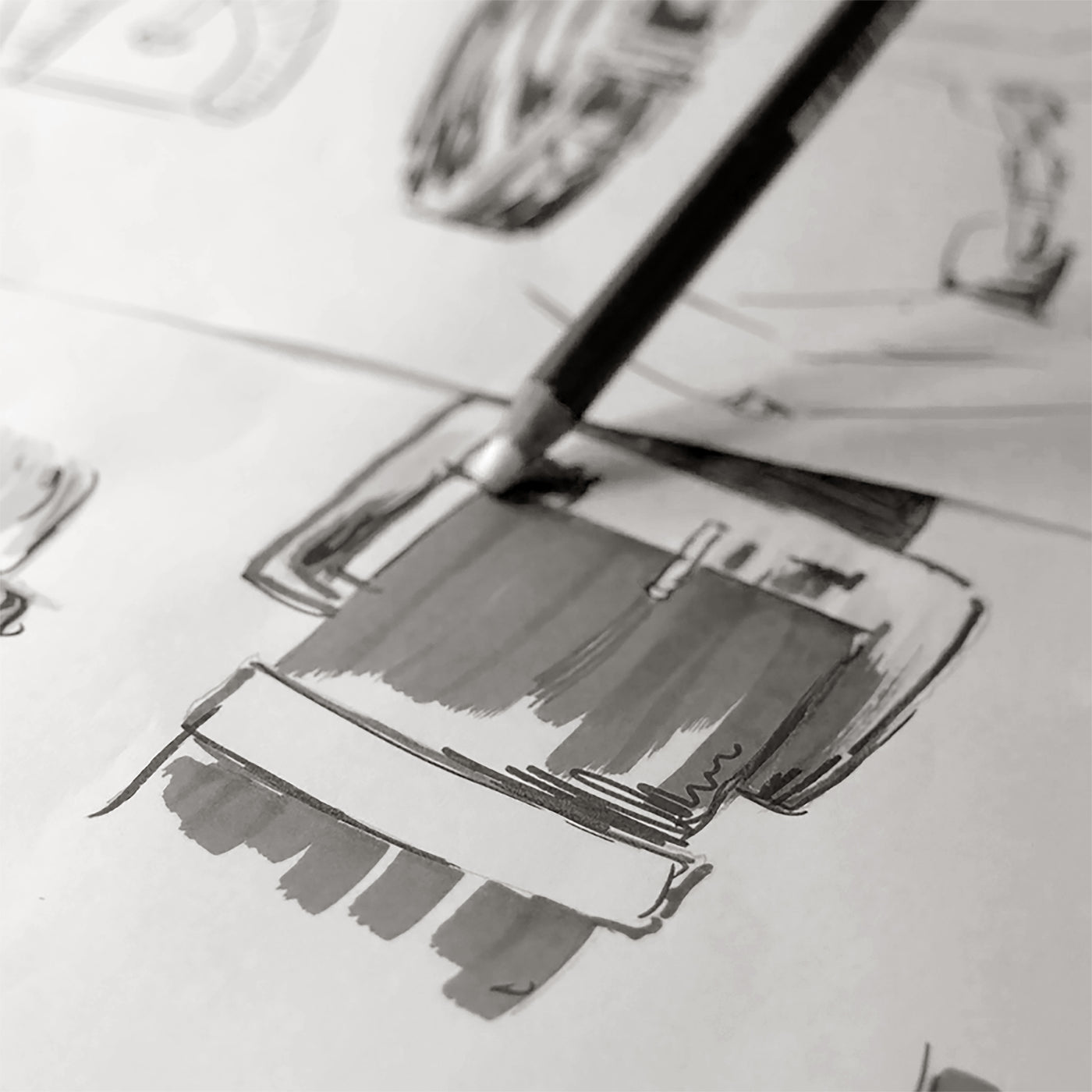

The artistic director visualises and devises models based on his inspirations and the latest trends.

A technical drawing is prepared in collaboration with the model-maker to pool all the information necessary for making samples (leather type, colours, dimensions and metal elements).

Each hide is meticulously inspected and checked by our warehouse supervisor.

This ensures our artisans are able to work with premium-quality leather.

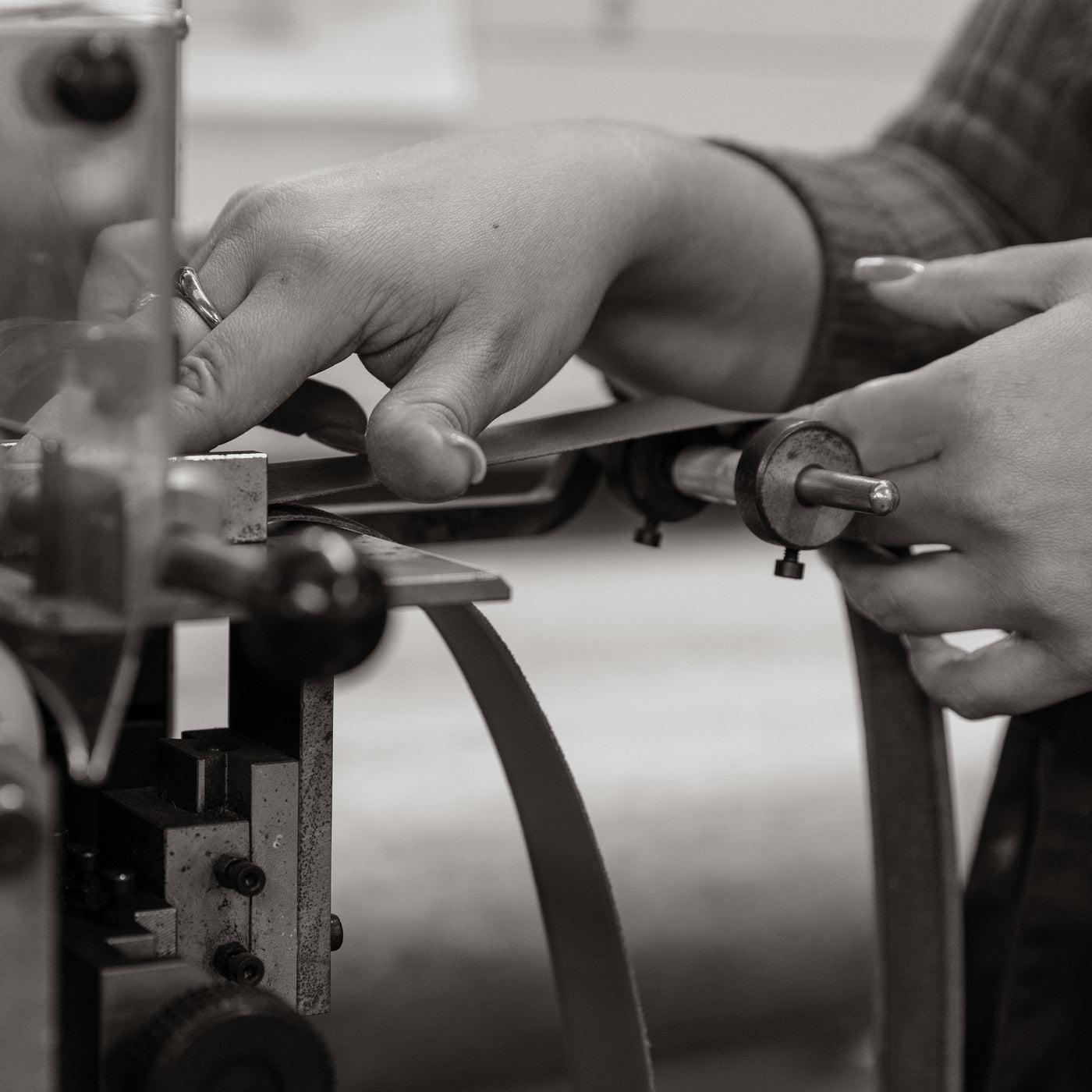

Our artisans precision-cut the various belt components, as per the technical drawing

This is essential for refining the material and preventing any excessive thickness when adding the lining to the strap. A crucial step.

In this step, the top part is delicately fused with the lining, creating what is referred to as the belt's body.

Holes are pierced at regular intervals, enabling the belt to be adjusted.

Our belts' edges are burnished, before an undercoat is applied once, twice or even three times, depending on the material and the desired finish.

Once this has been done, the belts can be dyed until totally smooth.

Stitching can be added around the body of the belt for optimum durability. But the belt can also be left plain with no stitching, or with a freehand edge grooving.

The last step, where the belt takes shape.

The belt strap is looped through the buckle and sewn together, fastening the buckle into place

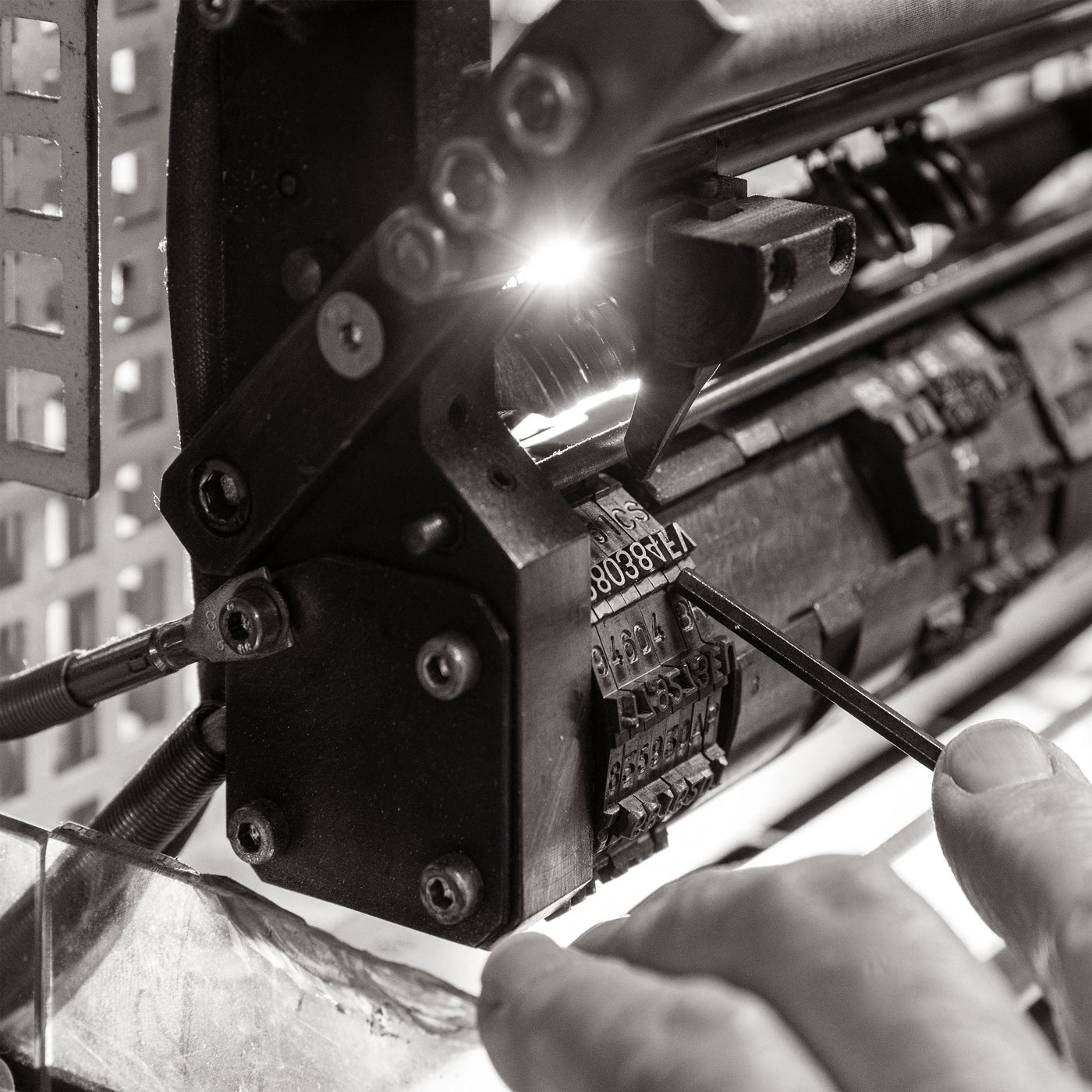

Our logo is heat-branded on the exterior or lining of the belt.

Depending on the product, this branding will show the model number, quality and size

Once created, the belt is checked meticulously.

Particular care is taken with examining the dyeing and stitching to ensure a perfect end result.

Each belt is given final aesthetic touches before being packaged and shipped.